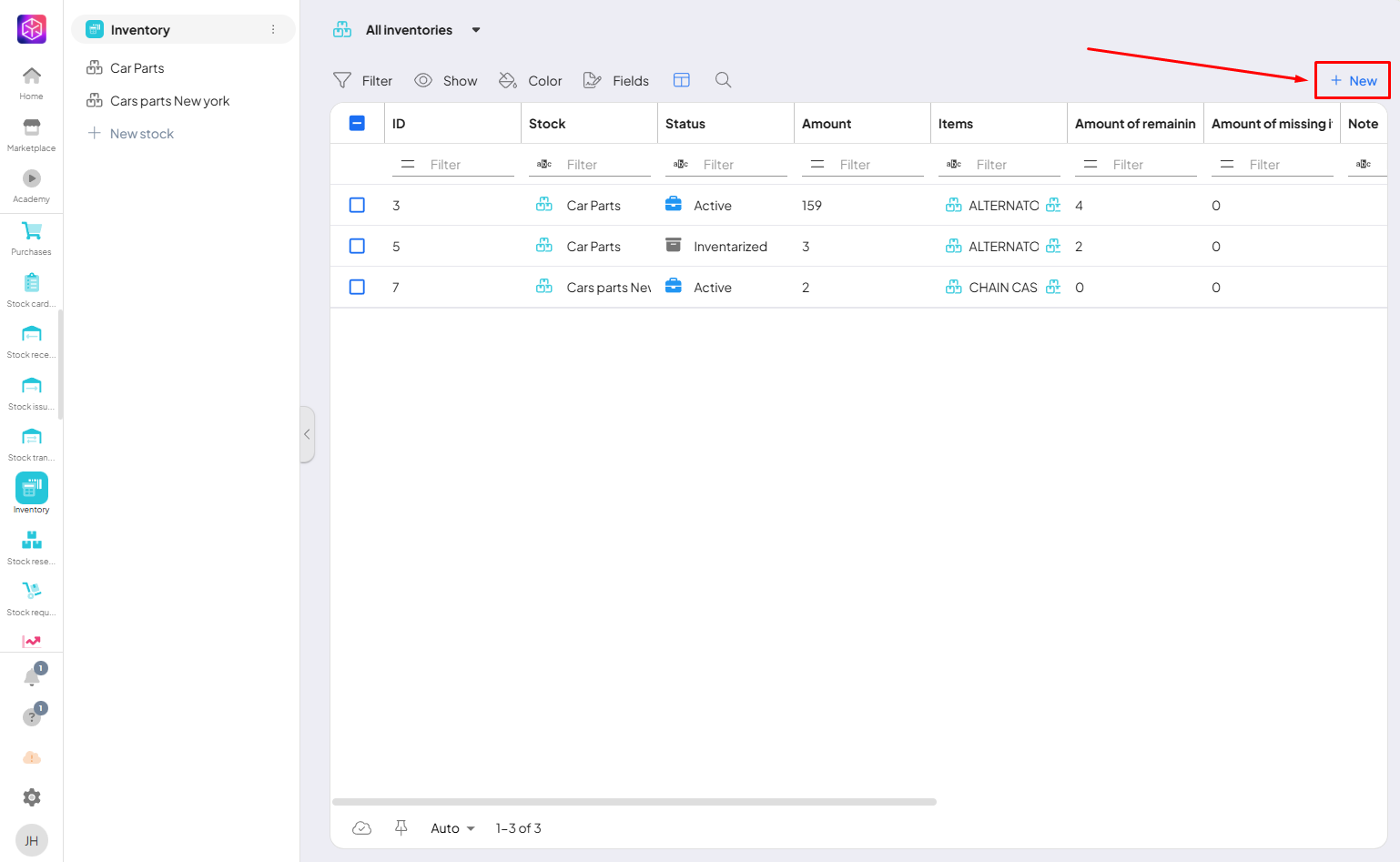

Comparison of recorded and physical inventories in Boost.space Warehouse management system

Inventory allows you to check and compare stock items in the Warehouses addonOne of the addons of the Boost.space system. With this addon, you can easily manage your business warehouses and inventory. with the actual quantity of stock itemsItems are rows in records (order/request/invoice/purchase...) in the warehouses.

The inventory can be company-wide for all warehouses at once, or it can be targeted according to:

- Warehouse – for which specific warehouse the inventory is prepared

- Type – filtering by stock itemItems are rows in records (order/request/invoice/purchase...) type

Inventory process

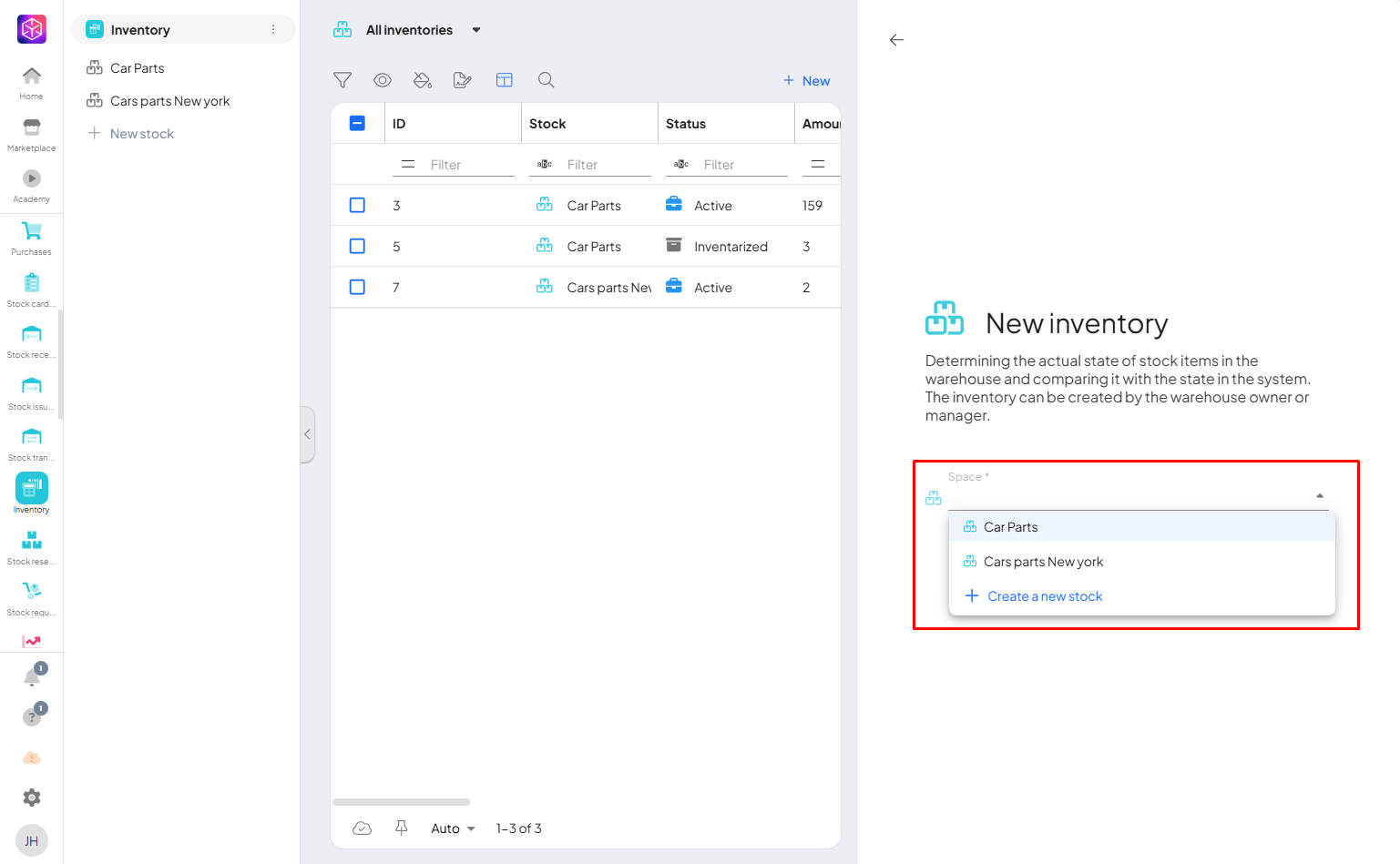

The inventory can be started by the OwnerIn Boost.space, an Owner is a role within a space that grants comprehensive control over that space. Owners can manage members, managers, and other owners, view and manage records, edit space settings—including status lists and labels—and have the authority to delete the entire space. or the Warehouse ManagerIn Boost.space, a Manager is a role within a space that allows an individual to manage members and other managers, view and manage records, and modify space settings, such as status lists and labels..

If you have more warehouses choose where you want to do the inventory.

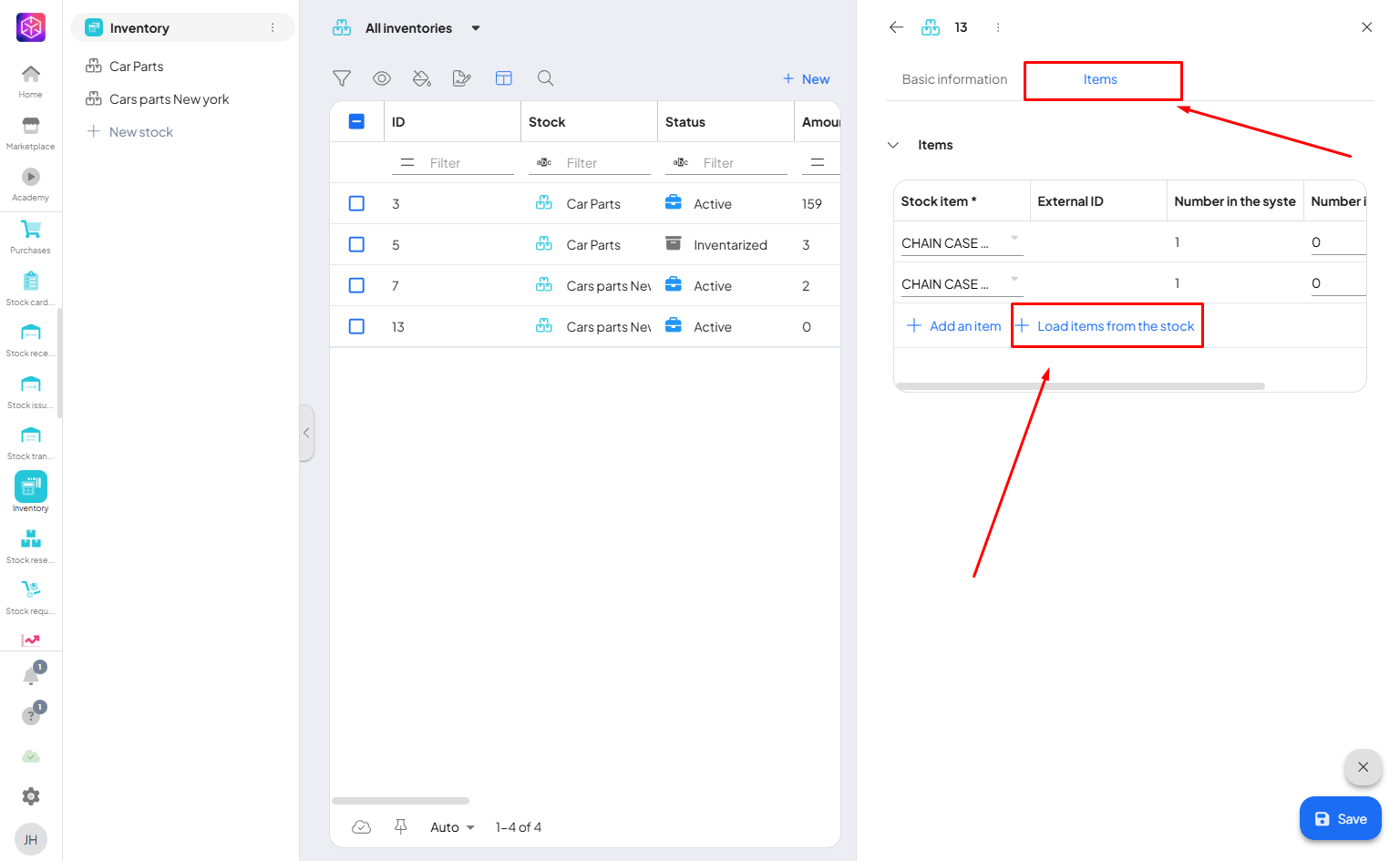

After creating an inventory and pressing the “retrieve items from warehouse” button, the warehouse items corresponding to the filtering set are displayed.

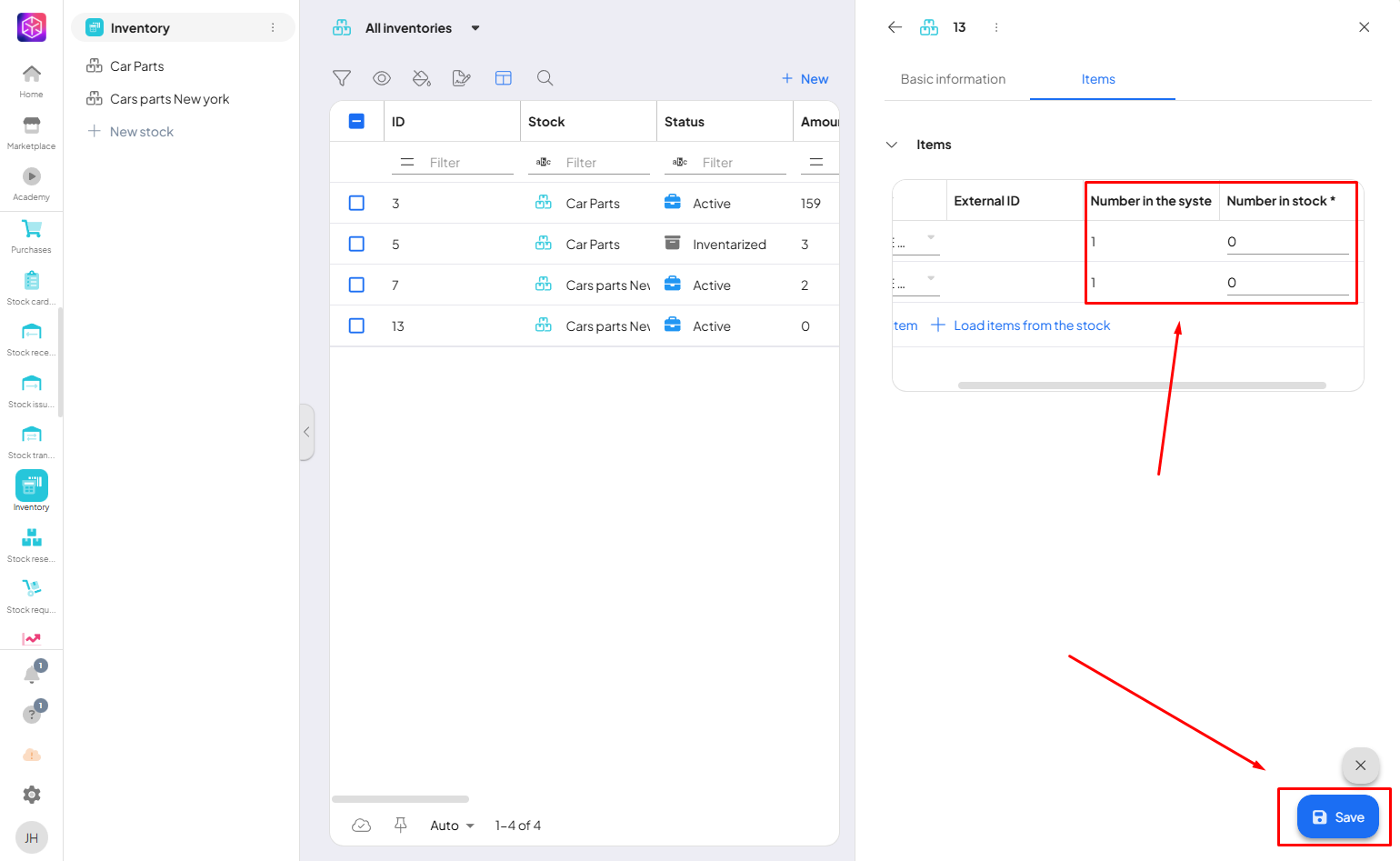

Each stock item has its current quantity in the Boost.space systemA platform that centralizes and synchronizes company data from internal and external sources, offering a suite of modules and addons for project management, CRM, data visualization, and more. Has many features to optimize your workflow!, which is compared with the actual stock levels found in the inventory.

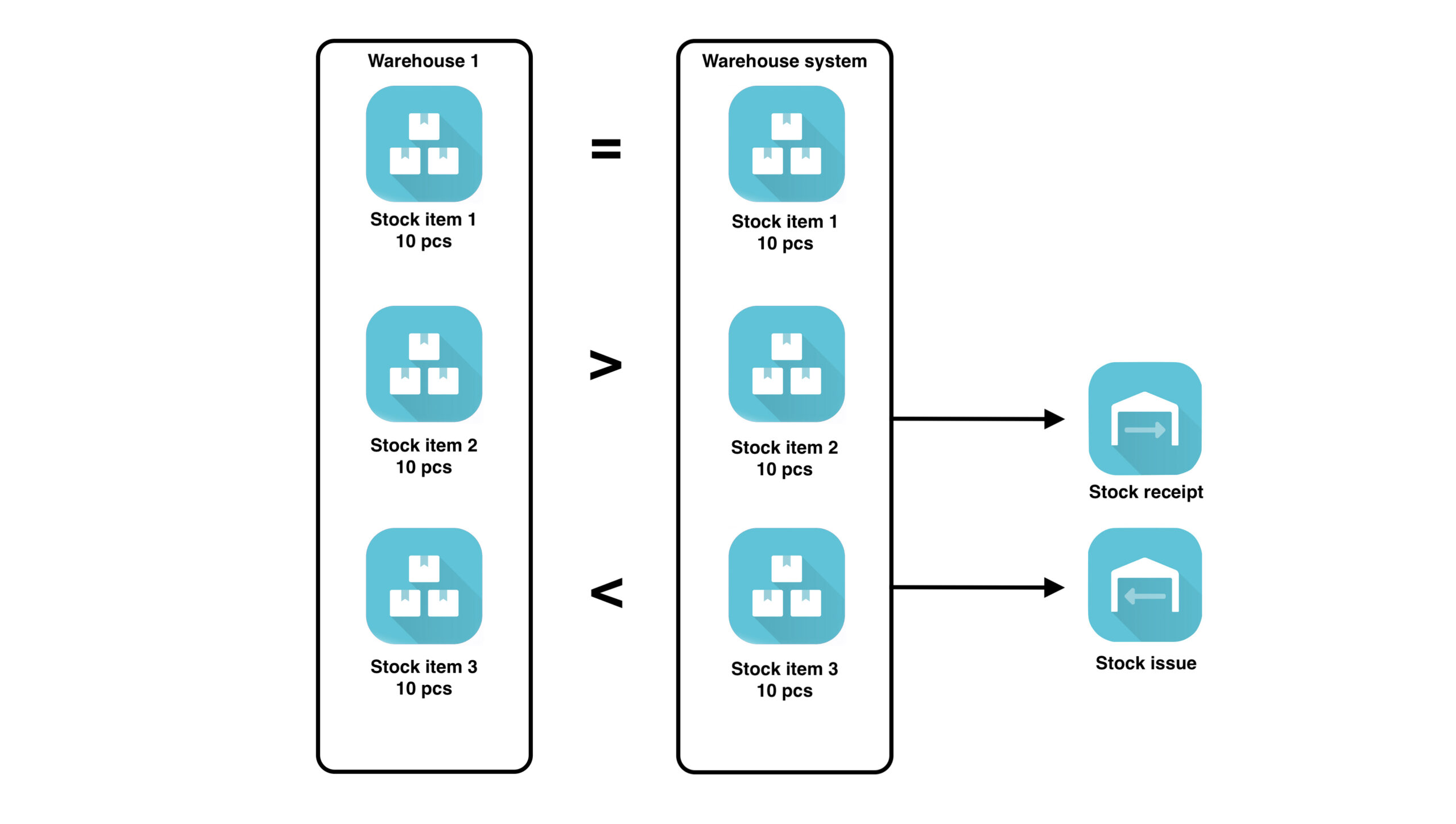

For each stock item in the inventory, one of three states can occur:

- quantity in system = quantity in stock → ideal state that does not require further action;

- quantity in the system > quantity in stock → stock item is missing in the warehouse, a receipt is automatically created to which you can add a comment;

- quantity in the system < quantity in stock → stock item in stock is overstocked, a receipt is automatically created to which a comment can be added.

Closed dispatches, receipts, and transfers

To maintain order in the warehouse system, dispatches, receipts, and transfers with a date before the inventory are locked after the completion of the inventory, and it is also possible to create receipts, dispatches, and transfers only with a later date than the inventory.

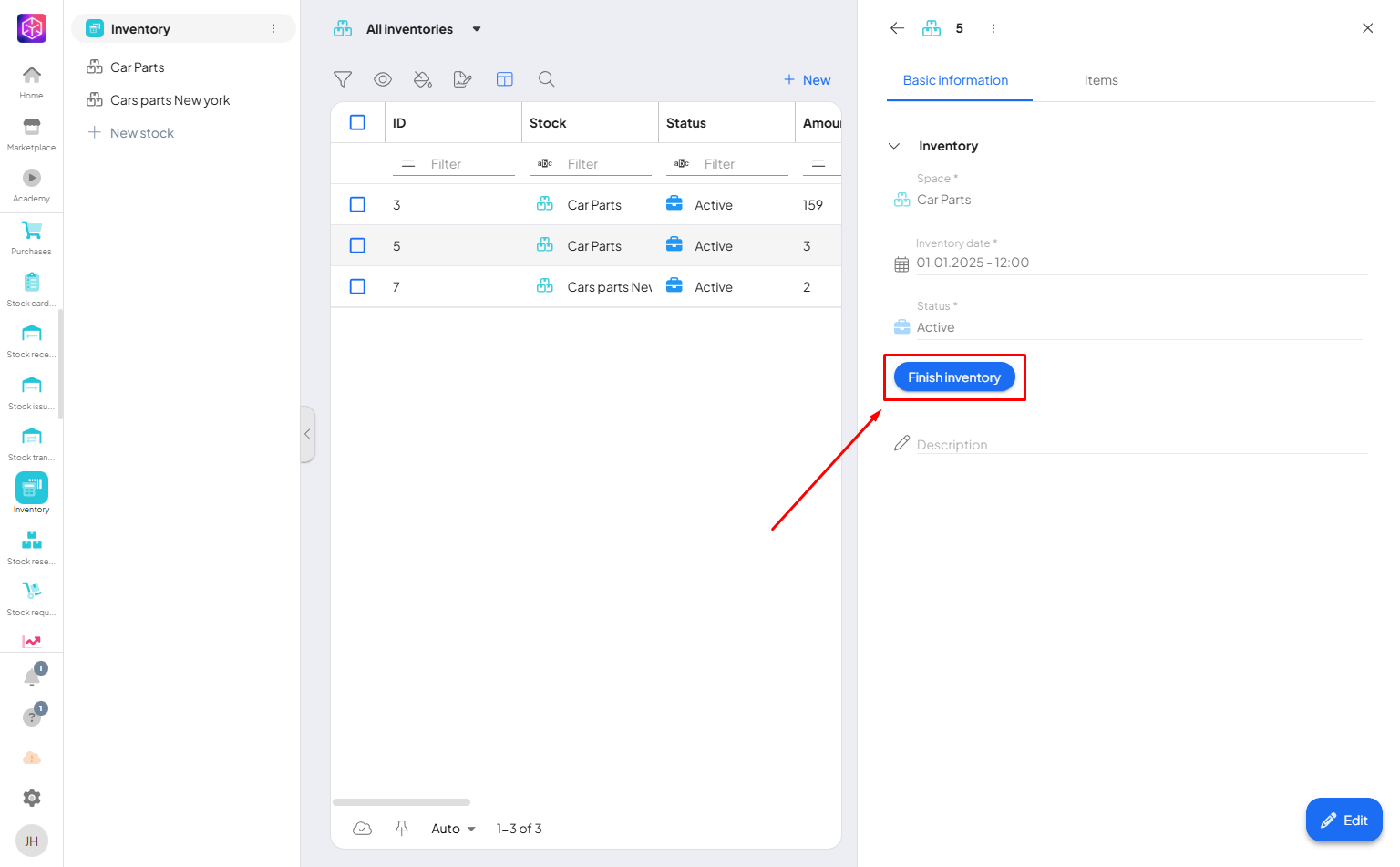

Lets say you did inventory 1.1.2025 and now you want to finish it. So click on “Finish inventory”.

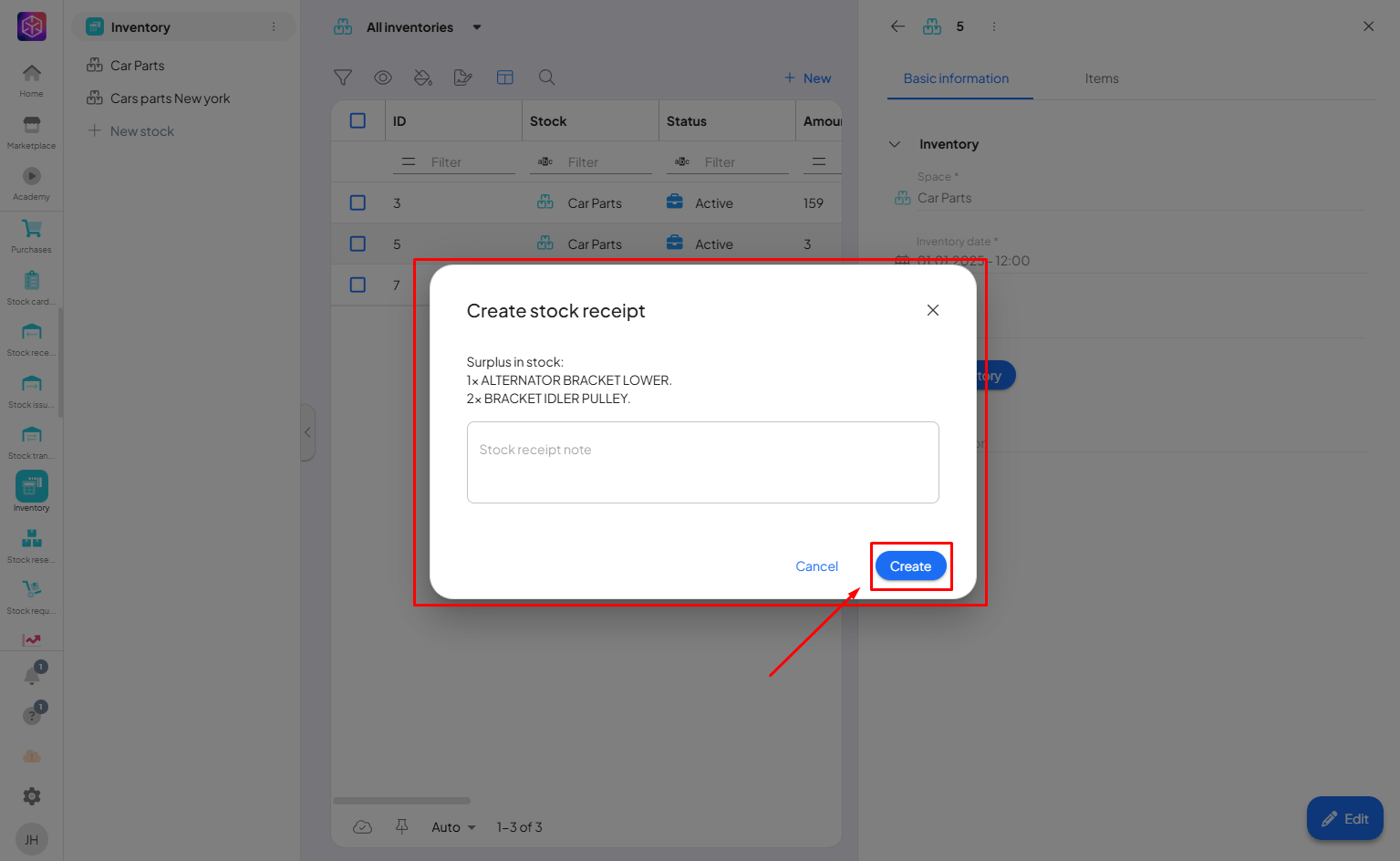

The system will automaticly create stock recipt or issue for you. You can also write note for this. Now just click “Create” and that is it.

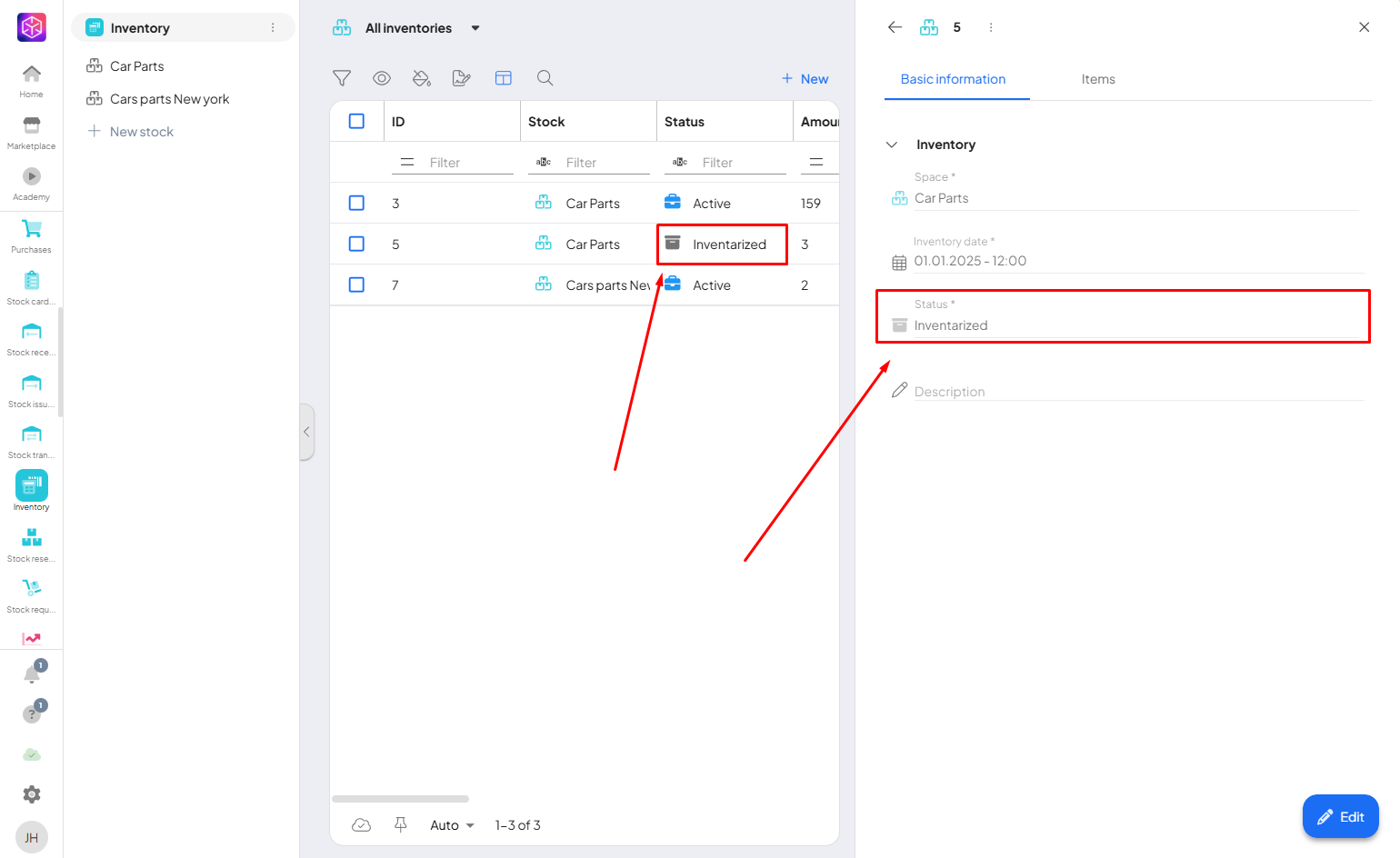

The system will change the statusIn Boost.space, statuses are indicators assigned to records within modules to represent their current state or progress. They can be system-defined, such as "Active" or "Done," or custom-created to fit specific workflows. Statuses help track and manage tasks, projects, and processes efficiently. to inventarized. And it is done!

System streamlines the comparison of recorded and physical inventories, ensuring accuracy and transparency in stock management. It automatically identifies discrepancies and creates the necessary stock receipts or issues to correct them. By locking past recordsIn Boost.space, a record is a single data entry within a module, like a row in a database. For example, a contact in the Contacts module or a task in the Tasks module. after inventory completion, the system maintains data integrity and simplifies the entire inventory process.

If you need help with anything, please contact us at support@boost.spaceA platform that centralizes and synchronizes company data from internal and external sources, offering a suite of modules and addons for project management, CRM, data visualization, and more. Has many features to optimize your workflow!.