Boost.Space Warehouse system: Unlimited catalogue and modular management

The stock card is the base for keeping track of goods and other stock itemsItems are rows in records (order/request/invoice/purchase...). It contains general information about the itemItems are rows in records (order/request/invoice/purchase...) handled in the warehouse (e.g. name, identifier, description, and other general information and values of these properties).

The stock card contains a list of all related stock items that are being dealt with across all warehouses. A stock card can be, for example, “iPhone 13 Pro” or “MacBook Air 13”.

Basic information:

- Code – automatically generated identifier;

- Name – the name of the stock card;

- Product – connectionUnique, active service acces point to a network. There are different types of connections (API key, Oauth…). to the Products moduleOne of the modules of the Boost.space system. In this module, you can easily manage your business products.. This is an optional field because the stock card can also be a material or other unrelated items with products (e.g. stock card for the product “shoes” and at the same time for the material “laces”, “leather” and others);

- SKU – Stock Keeping Unit, a unique code for product identification, compared to the EAN code, the SKU code can be defined in detail according to the company’s needs;

- External marking – the stock card marking used by the supplier or other interested parties;

- Currency – system currency, automatically pre-filled field;

- Type – type of stock cards/items that adminA user role in Boost.space with comprehensive system access, including the ability to add, remove, and manage all system levels. Admins can oversee all users, configure system settings, create custom fields, and manage modules and addons. Admin can also access Integrator and manage automations. can set in system settingsMain settings of the Boost.space system that is accessible only by admins. You can change a variety of things here (custom fields, actions and triggers, design, etc.) -> warehouses -> basic settings (e.g. “low shoes” “high shoes”);

- Count – the sum of stock items in the warehouse;

- Amount of reserved – the sum of currently reserved stock items;

- Number of ordered – the sum of currently ordered stock items;

- Average price – average price of stock items;

- OUM – unit of measure (e.g. pcs, kg, m2, etc.);

- Measurements

- Height (mm)

- Width (mm)

- Depth (mm)

- Note – any note on the stock card;

- Attachments – attachments attached to the stock card.

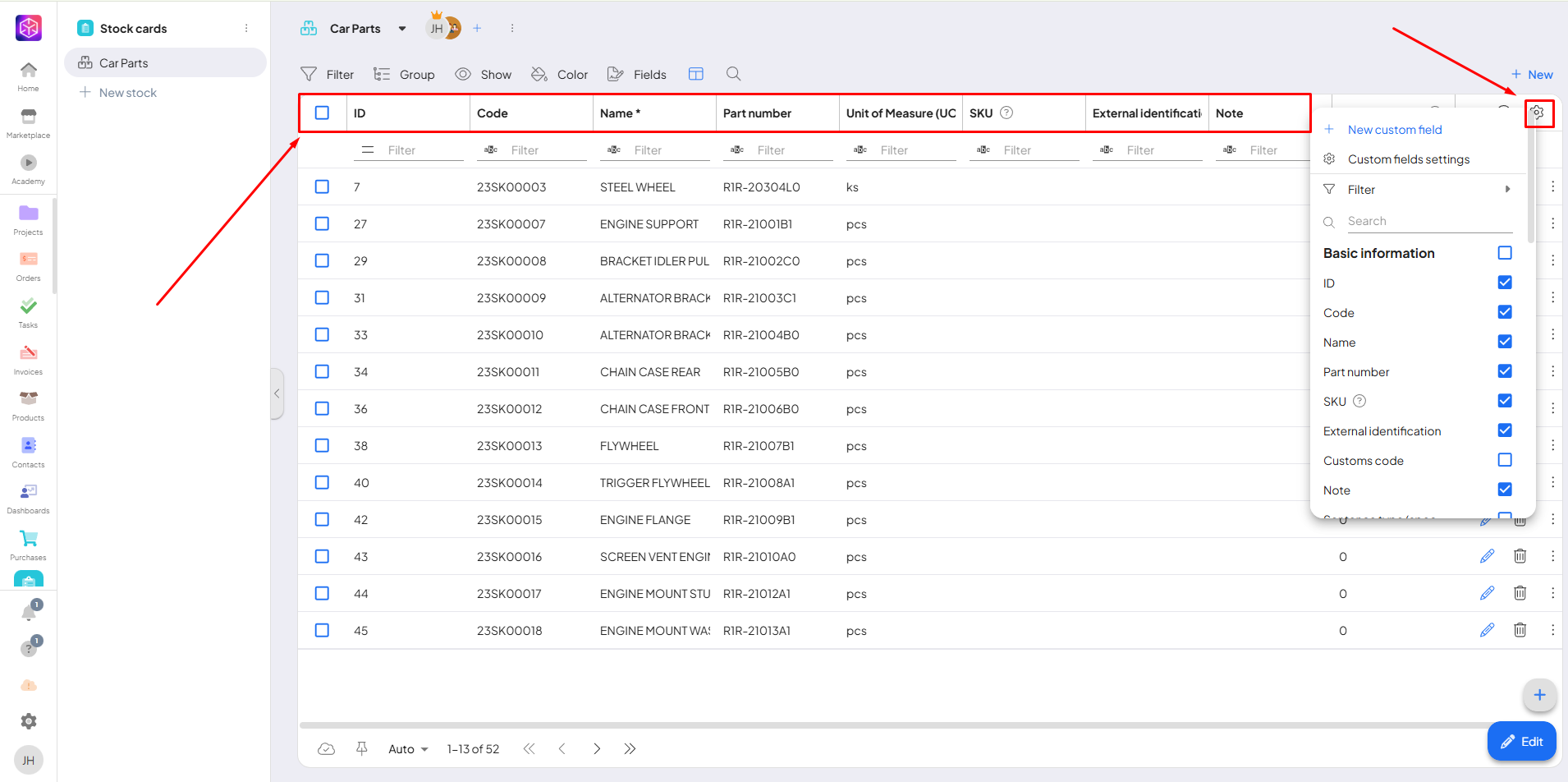

This basic information you can see in your spaceIn Boost.space, a space is a subunit within a module that helps organize and categorize data, ensuring clarity even with large volumes. For example, within the Contacts module, you might have spaces like "Client Database" or "Supplier Database." Access to each space is restricted to users who have created it or have been granted access.. If you dont want to see all this information, you can always select/deselect them. Just simply click on the gear icon and choose which informations you want to see.

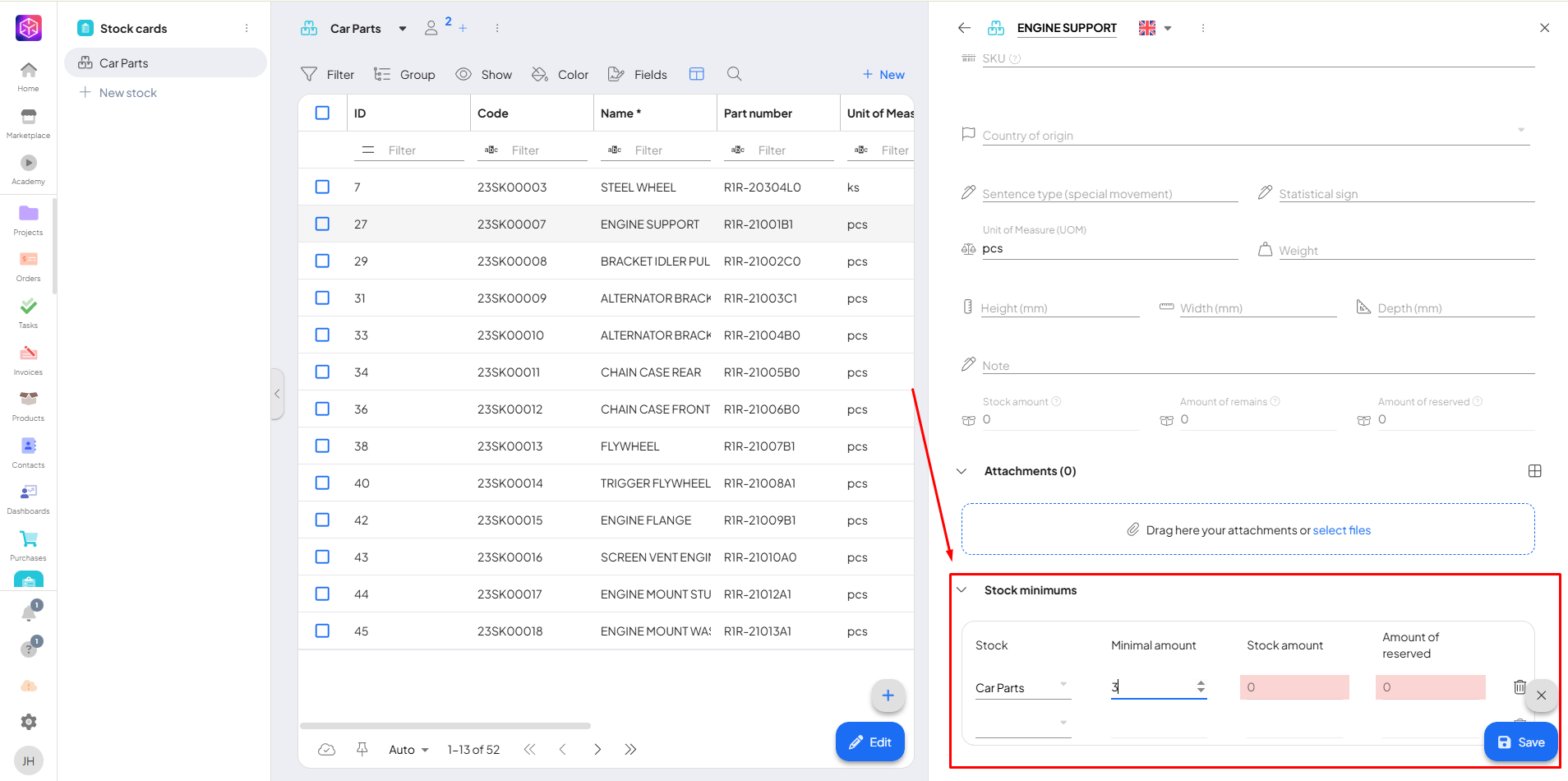

Stock minimums

In the details of each stock card, you can set stock minimums for specific warehouses. If the set minimum is exceeded by the current or reserved quantity of items, the fields are marked in red.

Stock items

Within the details of each stock card, it is possible to easily track the statusIn Boost.space, statuses are indicators assigned to records within modules to represent their current state or progress. They can be system-defined, such as "Active" or "Done," or custom-created to fit specific workflows. Statuses help track and manage tasks, projects, and processes efficiently. of individual stock items that are linked to a specific stock card. All information related to the stock item is available, such as its current stock count, suppliers, average price, and more. Stock item is one of the recordsIn Boost.space, a record is a single data entry within a module, like a row in a database. For example, a contact in the Contacts module or a task in the Tasks module. in your warehouse. Another records in your warehouse could be stock cards, stock issues, stock reservations etc. It’s similar to a recordIn Boost.space, a record is a single data entry within a module, like a row in a database. For example, a contact in the Contacts module or a task in the Tasks module. in your product database is called product. Record in your warehouse is called stock item.

For more information about stock item, check this article.

Purchases

An overview of all purchases (in the Purchases addonOne of the addons of the Boost.space system. With this addon, you can easily manage your business purchases.) of a specific stock card, containing information on quantity, price, VAT, description, and more.

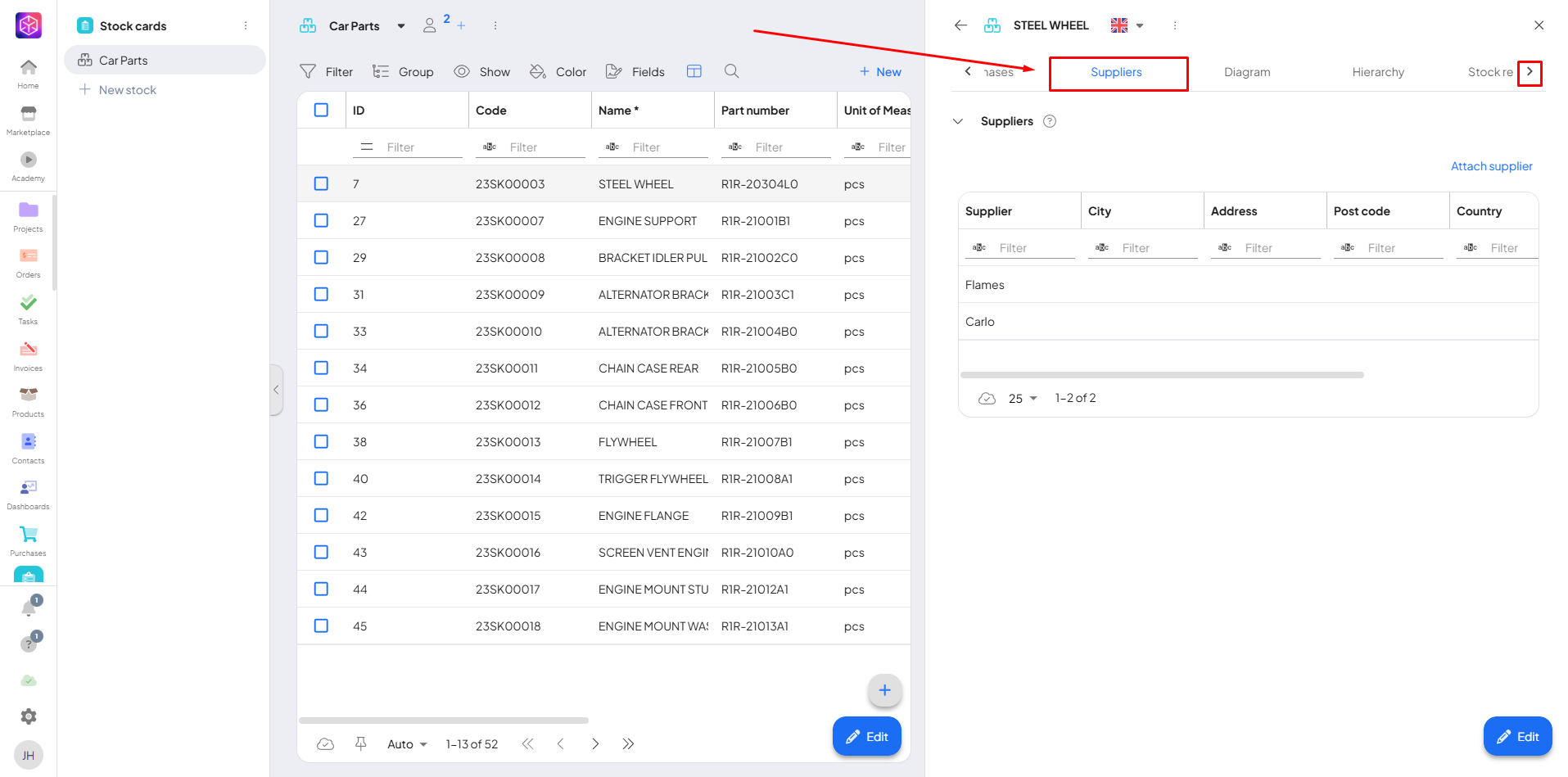

Suppliers

An overview of all suppliers of a specific stock card. Supplier data, such as their address and other relevant information, is displayed from the Contacts moduleOne of the modules of the Boost.space system. In this module, you can easily manage your business contacts. where it is stored.

DiagramThe diagram is a visual representation of your scenario and appears exactly the same way as you see your scenario in the Scenario editor. Use the diagram tab to quickly view: <br> the execution history of your scenario.<br> the number of operations and data consumed.<br> the controls to manage the scenario.<br>

Unique graphical representation of the hierarchy of stock cards and their interconnection. With this view you always have an overview of the related stock cards including the required quantity, for example, the stock card Table would be linked to the stock cards Table Top (1x), Table Leg (4x), Screw (4x) and Nut (4x).

By setting up detailed links between stock cards, you always have an overview of how much of a particular material is needed to produce the parent stock card (e.g. a table). This simplifies the commissioning of production or the purchase of missing quantities of materials and goods.

Hierarchy

The stock card hierarchy shows the parent and subordinate relationships of stock cards with their properties and information. In this view, some stock cards can appear in more than one place, for example, the stock card Screw can be subordinated to the stock card Table and the stock card Chair.

Requirements

Requests are used to produce/purchase the required quantity of material for a certain number of stock cards on a specified date. The requirements take into account the already reserved and ordered material, thus reflecting the actual reality and thus creating an important basis for further corporate decision-making.

Information related to the requirements:

- Total needed – the quantity needed according to the specified required quantity on the required date;

- On stock to requested date – the quantity in the warehouses on the set date;

- Reservation on the date of request – the reserved quantity on the requested date;

- Missing/surplus = total needed – in stock at the date of request + reserved at the date of request – ordered at the date of request;

- Ordered on date of request – the quantity purchased on the requested date;

- Average price/unit – recalculated average price per piece;

- Total estimated price = average price per piece * required number of pieces.

Stocks in time

An overview of inventories over time in a clear and simple way. See how the stock cards have evolved and have an overview of the expected stock levels in the future.

If you need help with anything, please contact us at support@boost.spaceA platform that centralizes and synchronizes company data from internal and external sources, offering a suite of modules and addons for project management, CRM, data visualization, and more. Has many features to optimize your workflow!.